Introduction:

Wine production generates substantial amounts of grape residue, commonly known as pomace or wine lees. Efficient management of this byproduct is crucial for sustainable and environmentally friendly winemaking practices. In recent years, the wine industry has embraced advanced technologies to address this challenge, with the introduction of the Wine Residue Dewatering Machine standing out as a game-changer.

Overview:

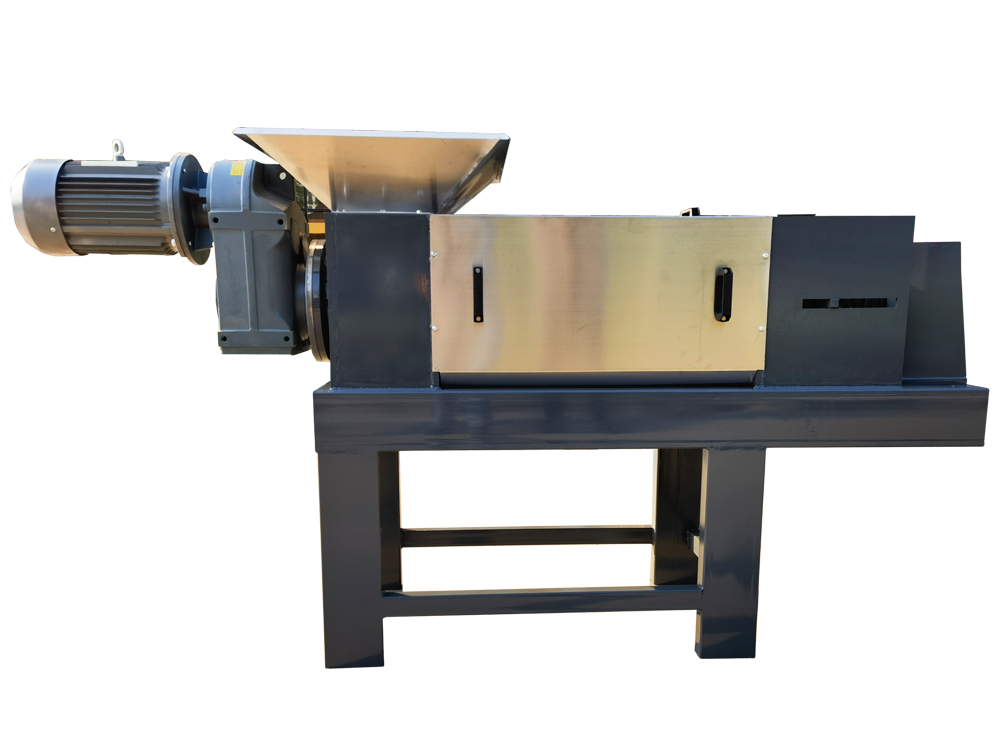

The Wine Residue Dewatering Machine is a state-of-the-art device designed to streamline the dewatering process of grape pomace, significantly reducing its moisture content. This innovative equipment not only aids in the effective disposal of winery waste but also presents opportunities for the extraction of valuable byproducts, contributing to a more circular and resource-efficient approach in winemaking.

Key Features:

High Dewatering Efficiency:

The machine employs advanced mechanical and/or hydraulic systems to exert pressure on the grape residue, effectively separating water from the solid components. This results in a substantial reduction in moisture content, facilitating easier handling and disposal.

Customizable Design:

Wine Residue Dewatering Machines come in various sizes and configurations, allowing wineries to choose a model that aligns with their production scale and specific requirements. This versatility enhances the adaptability of the equipment across different winemaking operations.

Byproduct Recovery:

Beyond dewatering, some machines are equipped with additional features for extracting valuable byproducts from the grape pomace. This includes recovering residual wine, grape seed oil, or other compounds that can be repurposed or sold, providing an additional revenue stream for wineries.

Energy-Efficient Operation:

Modern dewatering machines are designed with energy efficiency in mind, incorporating smart technologies to optimize power consumption. This not only reduces operational costs but also aligns with the global push towards sustainable and eco-friendly manufacturing processes.

Benefits:

Waste Reduction:

By significantly reducing the moisture content of grape pomace, wineries can minimize the volume of waste generated during the winemaking process. This, in turn, alleviates the environmental impact associated with waste disposal.

Cost Savings:

The recovery of valuable byproducts translates into potential cost savings for wineries. The extracted materials can be utilized internally or sold to other industries, contributing to a more economically viable and sustainable business model.

Compliance with Environmental Regulations:

Utilizing a Wine Residue Dewatering Machine enables wineries to meet and exceed environmental regulations regarding waste management. This proactive approach not only fosters a positive public image but also ensures long-term sustainability in the industry.

Conclusion:

The Wine Residue Dewatering Machine represents a significant leap forward in winery waste management, offering a multifaceted solution to the challenges posed by grape pomace. By efficiently reducing moisture content and extracting valuable byproducts, this technology is reshaping the landscape of modern winemaking, fostering a more sustainable and environmentally responsible industry.

TEL:+86 17753651813

TEL:+86 17753651813

EMAIL:liumeifang@chuantaimc.com

EMAIL:liumeifang@chuantaimc.com

WeChat:17753651813

WeChat:17753651813

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China

Copyright © 2022-2024 Chuantai Machinery, INC. All Rights Reserved.

sitemap Screw Press Dewatering Machine